Discover unmatched precision and reliability with the FLAW HUNTER S 9603 — Pejvak Rayan’s cutting-edge ultrasonic immersion scanner engineered for high-sensitivity, 3D flaw detection and thickness measurement. This ultrasonic immersion test system delivers laboratory-grade accuracy in industrial conditions, making it the trusted choice for critical inspections. With upgradeable channels, modular design, and proven performance across metals, plastics, and composites, it’s the intelligent solution professionals rely on when quality cannot be compromised.1

High-precision 3D ultrasonic immersion scanner for accurate HIC and flaw detection in metals, composites, and welds.1

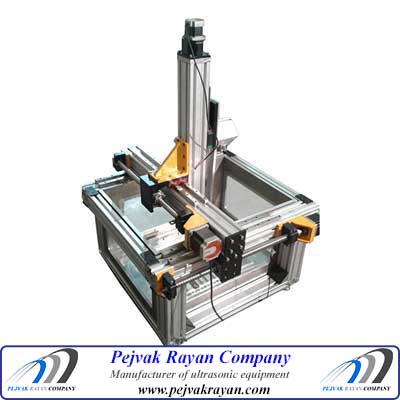

Pejvak Rayan also designs and manufactures this type of immersion ultrasonic testing scanner for plate inspection as a custom-built solution tailored to customer requirements.1

Pejvak Rayan – FLAW HUNTER S 9603

The FLAW HUNTER S 9603 by Pejvak Rayan is a high-precision ultrasonic immersion test system designed for 3D scanning and inspection of metallic and non-metallic components. Engineered to meet stringent industrial standards, this immersion scanner offers exceptional capabilities in both fault detection and thickness measurement. Though the base unit is a single-channel system, it is fully upgradeable to a 4-channel configuration to support advanced testing scenarios.1

1

In this ultrasonic immersion test, both the probe and the test sample are fully submerged in a water tank, ensuring optimal coupling and enhanced defect detectability. The system is capable of identifying micro-level flaws, including surface-adjacent defects as small as 0.4 mm. This method ensures consistent acoustic transmission, enabling highly accurate and repeatable results across a wide range of materials—metal, polyethylene, and composite plastics.1

The 3D immersion scanner generates high-resolution B-Scan, C-Scan, and full 3D images, allowing for in-depth visualization of internal defects, laminations, and cracks. It supports offline image processing, storage of test results, and detailed data reporting—ideal for quality assurance and third-party inspection validation. The system features automated CAR (Crack Area Ratio) calculation and pinpoints defect positions with 0.1 mm accuracy.1

With compact dimensions (400 × 350 × 300 mm), this ultrasonic immersion test system is ideal for lab-scale and industrial applications. Larger custom dimensions are available upon request. Built on precision ball screw drives and high-quality linear guides, the scanner delivers positioning accuracy of ±0.02 mm via encoder-based motion control on all X, Y, and Z axes.1

The immersion scanner supports waterproof transducers in the 2–20 MHz frequency range, selectable based on the material and inspection requirements. These probes offer outstanding resolution and are particularly effective in detecting near-surface flaws.2

Operators can easily export and analyze strip chart, B-Scan, C-Scan, and 3D data offline. The immersion scanner processes internal defect depth and location with unmatched clarity and precision, ensuring full confidence in each inspection result.1

FLAW HUNTER S 9603 ( Immersion Scanner) – Technical Specifications | ||

Values | Specification immersion scanner | No |

L × W × H = 400 × 350 × 300 mm (customizable) | Testable Part Dimensions | 1 |

Flaw detection and thickness measurement | Functionality | 2 |

Metals, non-metals, polyethylene, ceramics, plastics, etc | Material Compatibility | 3 |

0.05mm | Thickness Measurement Accuracy | 4 |

0.1mm diameter void | Minimum Detectable Defect | 5 |

Hydrogen-Induced Cracking (HIC), inclusions, air pockets, porosity, delamination | Detectable Flaws by immersion scanner | 6 |

3D Image, A-Scan, B-Scan, C-Scan, Strip Chart | Display Modes | 7 |

Highly Automated: The process is operator-independent, ensuring consistent and unbiased results.1

Cost-Effective: Requires no consumables or couplants, significantly reducing operational costs.1

Standards-Compliant: Accepted by global industry standards, including oil & gas, aerospace, and petrochemical sectors.1

High Resolution immersion scanner: Detects internal flaws down to micron-level precision.1

Thick Material Compatibility: Capable of inspecting parts up to 200 mm in thickness.1

Dual-Functionality: Simultaneous flaw detection and thickness measurement in one cycle.1

Immediate Decision-Making: Automatic classification of parts as pass/fail based on embedded standards eliminates the need for onsite inspectors.1

Manufactured in Iran by Pejvak Rayan, the FLAW HUNTER S 9603 is a state-of-the-art ultrasonic immersion scanner designed for professionals who demand accuracy, efficiency, and scalability. Its modular design allows for tailored configurations, ensuring seamless integration into any inspection workflow—whether you’re testing standard steel plates or composite structures via Through-Transmission Testing.1

With over a two decade of experience and expertise, Pejvak Rayan is a trusted manufacturer of advanced ultrasonic testing and inspection systems. If you’re looking for precision, reliability, and cost-efficiency، our solutions are built for you.1

Our systems and immersion scanner are engineered with the latest technologies and comply with international standards. They are designed for high-accuracy flaw detection and fast processing, compatible with various metal products including pipes, billets, rebars, ingots, sheets, and plates.2

We believe advanced technology should be accessible. That’s why our pricing is highly competitive — especially for companies across Asia — while maintaining superior performance and build quality.3

Our expert engineers provide on-site installation and full training to ensure your team maximizes the system’s potential from day one.4

We don’t stop at delivery. Our dedicated support team offers technical assistance, spare parts, and repair services to keep your operations running smoothly.5

Serving clients across Asia — from Turkey, Pakistan, and the Middle East to India, Southeast Asia, and Central Asia — we are ready to be your reliable partner in ultrasonic testing.1

Experience world-class technology with region-friendly pricing

Contact us today for a free consultation for immersion scanner and learn how Pejvak Rayan can upgrade your quality control process.1

For more information about immersion scanner , please send your request to info@pejvakrayan.com

or contact us via

WhatsApp number +989195103539, +989196350307

Support staff

Immersion Ultrasonic Testing Scanner for Plate Inspection

Strip Inspection System – UT test

Online corrosion monitoring system _ ut

Ultrasonic Scanner – R-Scan Corrosion Inspection Scanner

lamination test – Plate UT Testing Trolly

Round Bar inspection system – UT test

Spiral SAW Pipe Inspection System – Ultrasonic Steel Weld Testing

Immersion Scanner for HIC – ultrasonic test

Automated Ultrasonic Corrosion Mapping (AUT) scanner

ERW pipes inspection system – weld Ultrasonic Testing machine

Touch Screen Flaw Detector – Ultrasonic technology

CNG Cylinder Ultrasonic Testing Inspection system

Pipe Inspection System – Ultrasonic equipment

Billet Inspection System – UT test

ضخامت سنج التراسونیک پژواک رایان

All Rights Reserved by Pejvak Rayan Co