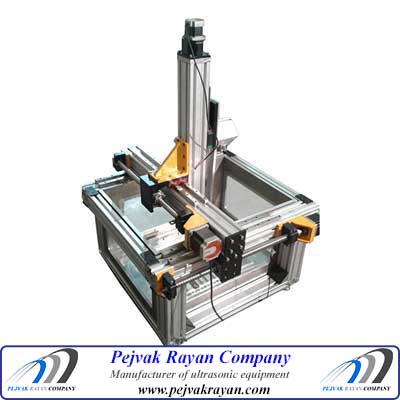

Ultrasonic immersion test system – 3D scanner Pejvak Rayan (FLAW HUNTER S 9603) It is a single-channel device with the ability to upgrade to 4 channels according to the customer’s request. This Ultrasonic immersion test system – 3D scanner is capable of simultaneous thickness measurement and fault diagnosis of metal, non-metal, polyethylene and plastic samples.

Due to the high sensitivity of this system in identifying very small defects (about 0.4 mm) and defects close to the surface, as well as ensuring the uniformity of the coupling between the probe and the tested piece, this test is performed with the full immersion technique. In the ultrasonic immersion test, the probes and the test piece are completely placed in the water tank.

Detection of defects from a depth of 1 mm from the surface to a depth of 1 mm from the floor

Providing color B-Scan and C-Scan images and 3D image of the piece

Ability to process images and test results offline and save test results to present to inspectors

Automatic calculation of CAR (Crack Area Ratio)

Determining the position of defects with an accuracy of 0.1 mm

Thickness measurement and simultaneous troubleshooting

Reproducibility equal to POD >99%

The dimensions of this scanner are equivalent to (L x W x H = 400 x 350 x 300 mm). Scanners with larger dimensions can be custom made according to customer needs.

Due to the use of standard and accurate rails and carriages and the ball screw system in the movement of each axis and controlling the amount of movement of each axis through the encoder, this scanner has a movement accuracy of up to 0.02 mm.

In the ultrasonic immersion test system, waterproof probes with frequencies of 2-20 MHz (according to the part under test) have been used ,These probes have very high sensitivity and resolution to identify defects close to the surface.

The user will be able to upload the results stored in the strip chart and color images B, C-Scan and 3D image offline. This 3D scanner analyzes and examines the exact depth and location of defects inside the part with an accuracy of 0.1 mm.

It is done by an operator. Due to its high automation capability, it is not possible for the operator to interfere in the testing process.

It does not require consumables, so the test is inexpensive.

All the test information is recorded automatically and the rejection or acceptance status of the part according to the standard is determined immediately. Therefore, the presence of the customer inspector is not required.

In addition to troubleshooting, there is also the ability to measure the thickness of parts (without the need for physical contact with both surfaces of the part).

The standards of this test are accepted by all industries in the world.

The accuracy of the test in detecting internal defects is very high and in some cases it is in the range of microns.

It is possible to diagnose parts with high thicknesses, even 20 cm.

For more information, please send your request to info@pejvakrayan.com

or contact us via

WhatsApp number +989197313301

Support staff

Download Catalog

Online corrosion monitoring system _wireless ultrasonic inspection

manual Ultrasonic Scanner – R-Scan Corrosion Inspection Scanner

Plate Ultrasonic Testing Trolly – inspect sheet lamination defect

Round Bar inspection system – Automatic Ultrasonic Testing

Spiral SAW Pipe Inspection System – Ultrasonic Steel Weld Testing

Ultrasonic immersion test system – 3D scanner

Automated Ultrasonic Corrosion Mapping (AUT) scanner

ERW pipes inspection system – Automated Ultrasonic Testing

Touch Screen Flaw Detector – Ultrasonic technology

CNG Cylinder Ultrasonic Testing Inspection system

Seamless pipe ultrasonic inspection system

Ultrasonic Billet Inspection System

All Rights Reserved by Pejvak Rayan Co