ERW pipes inspection system – Automated Ultrasonic Testing, Pejvak Rayan (FLAW HUNTER EP 9501) is an online system that is used to detect longitudinal flaws of the welds, in ERW pipes and square profiles in online mode.

According to standards and ERW pipe and profile manufacturers’ needs, online ERW weld ultrasonic system is necessary and inseparable part of the production.

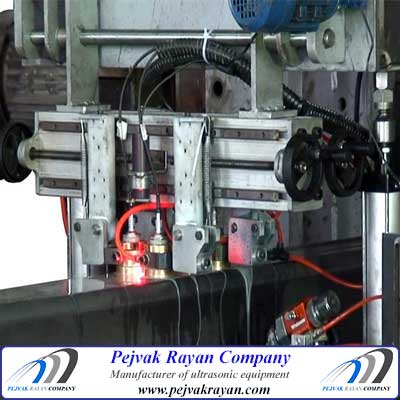

For testing these pipes with ultrasonic method, we need especial mechanical system, with capability of holding, moving and setting at least 4 probes separately.

ERW pipes inspection system is a special mechanical system that has the ability to hold, move and adjust at least four probes separately.

The probes are placed besides of the weld, because the waves propagated by them must be in vertical position to be able to detect longitudinal imperfections according to standards.

ERW pipe ultrasonic inspection system includes 4 separate angle probes and channels that probes are placed in especial holders and use water gap technique and each pair are placed in front of each other.

One pair is used for detecting longitudinal surface defects and other pair for longitudinal root defects in the weld.

FLAW HUNTER EP 9501 can be installed just after the welding machine in production line and can use the line’s Couplant for cooling and testing.

ERW pipe weld ultrasonic inspection system is capable of testing with high speed (60m per minute), because it has high PRF and powerful software filtering which can filter the electronic noises created by high frequency voltage of welder machine, annealer and electromotors that are working nearby.

The software of ERW pipe inspection system records all the test results in separate strip charts and is able to analyze the location and depth of the flaw.

If there is a flaw, the alarms go off and a paint spray automatically marks the faulty area.

Dimensions of products : Pipes from 4 to 24 inches – square profiles up to 400 mm

Thickness of product : 3 to 30mm

Material of products : Carbon Steel and Alloy steel (High, medium, low, stainless)

Speed of the test: Maximum 60 m per min

Detectable flaws: The flaws equal to N5 notch and 1.6 through hole

Weld condition: Top and bottom flash of the weld mut be trimmed

Test area: Full welded area plus 1.6 mm of the HAZ area

For more information, please send your request to info@pejvakrayan.com

or contact us via

WhatsApp number +989197313301

Support staff

Download Catalog

Online corrosion monitoring system _wireless ultrasonic inspection

manual Ultrasonic Scanner – R-Scan Corrosion Inspection Scanner

Plate Ultrasonic Testing Trolly – inspect sheet lamination defect

Round Bar inspection system – Automatic Ultrasonic Testing

Spiral SAW Pipe Inspection System – Ultrasonic Steel Weld Testing

Ultrasonic immersion test system – 3D scanner

Automated Ultrasonic Corrosion Mapping (AUT) scanner

ERW pipes inspection system – Automated Ultrasonic Testing

Touch Screen Flaw Detector – Ultrasonic technology

CNG Cylinder Ultrasonic Testing Inspection system

Seamless pipe ultrasonic inspection system

Ultrasonic Billet Inspection System

All Rights Reserved by Pejvak Rayan Co