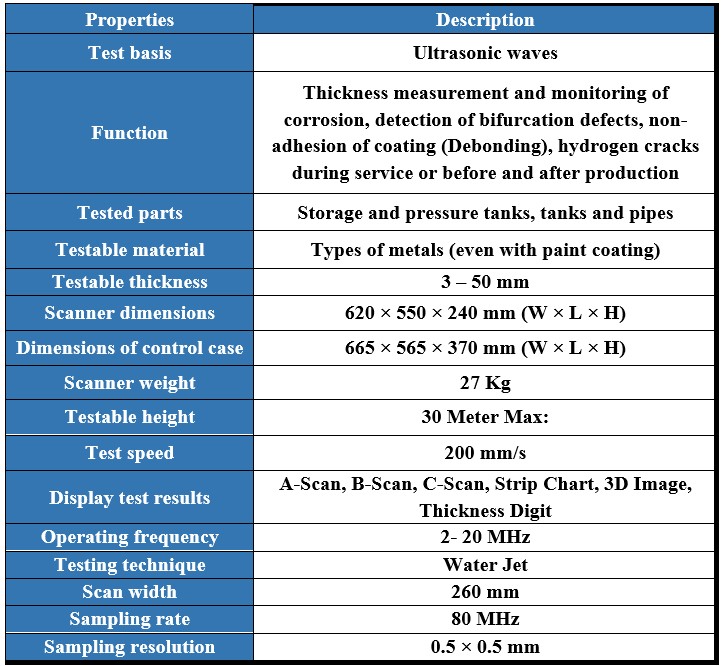

One of the most advanced ultrasonic systems available is the Pejvak Rayan Company’s Automated Ultrasonic Corrosion Mapping (AUT) scanner (FLAW HUNTER CR 9925), which can test, recognize, and display the degree of wall corrosion of pressure vessels, tanks, and pipes at a high speed and with complete automation. Two independent electric motors power the four moving magnet wheels of the Ultrasonic Corrosion Mapping Scanner. Additionally, it includes a unique holding probe and an internal high resolution probe that uses waterjet technique. An electric motor and encoder allow the probe to move back and forth across the scanner. Siemens PLC controller guides and controls the motors and motions of this scanner.1

Keeping the user and the electrical part of the equipment on the ground, this remote control scanner can climb and test the tank wall up to a height of 30 meters. This scanner’s main head is replaceable and may be modified to inspect curved surfaces, such pipes and small-diameter tanks.The equipment can test surfaces and pipes with curvatures up to 32 inches in diameter as a result to this capability. 3

The FLAW HUNTER CR 9925 scanner’s unique mechanisms and controllers allow it to clim the vertical walls of tanks and pressure vessels. Additionally, it accurately, quickly, and automatically scans the entire wall, giving the user useful details regarding internal defects, the rate of inner wall corrosion, and the wall’s overall thickness.2

Monitor corrosion in the inner wall, without the need to access the inside of the tanks

Identify a variety of defects of lamination, corrosion, hydrogen cracks and non-adhesion of coatings

High test speed up to 200 mm/s

Very high probability of defect detection (POD) because of the 0.5 mm scan resolution, accurate scanner movements, and real-time online recording of all received data.4

the capacity to record test data and plot results in C-scan and colored B-scan diagrams.5

Show an illustration of the wall thickness in three dimensions.6

Capacity to test flat surfaces and pipes with a diameter of 32 inches or more

Test at up to 30 meters in height without requiring the operator to climb, and establish the operator’s safety.7

Capacity for inspecting painted surfaces

Assess and analyze test findings offline

Test results are automatically documented without operator intervention.8

Reduce operator errors to almost zero by fully automating testing and recording results.9

The device’s portability allows for easy movement to the testing location.10

The entire wall of the pressure vessels, tank, and pipe are inspected by the Automated Ultrasonic Corrosion Mapping (AUT) scanner at a resolution of 0.5 x 0.5 mm. All the data acquired is displayed, along with any defects, in the color C-scan graphic. Additionally, this scanner can produce a three-dimensional image that shows the thickness of the tank wall. The ultrasonic corrosion mapping scanner is in charge of providing the coupling at high altitudes and is supplied with a stainless steel tank and a specialized electric pump. The scanner’s automation and electronic components are all placed in a carry-on luggage that the operator can quickly move to the test location.11

For more information, please send your request to info@pejvakrayan.com

or contact us via

WhatsApp number +989197313301

Support staff

Download Catalog

Online corrosion monitoring system _wireless ultrasonic inspection

manual Ultrasonic Scanner – R-Scan Corrosion Inspection Scanner

Plate Ultrasonic Testing Trolly – inspect sheet lamination defect

Round Bar inspection system – Automatic Ultrasonic Testing

Spiral SAW Pipe Inspection System – Ultrasonic Steel Weld Testing

Ultrasonic immersion test system – 3D scanner

Automated Ultrasonic Corrosion Mapping (AUT) scanner

ERW pipes inspection system – Automated Ultrasonic Testing

Touch Screen Flaw Detector – Ultrasonic technology

CNG Cylinder Ultrasonic Testing Inspection system

Seamless pipe ultrasonic inspection system

Ultrasonic Billet Inspection System

All Rights Reserved by Pejvak Rayan Co